Making our clients look good

Dinosaur Head

This fun project saw the Lane Co. team produce a dino-head display for a toy product.

The client approached us with a 3-D model of the injection-molded parts that made up the toy. Our team took these files, scaled them up accordingly for use as a display, and modified them for thermoforming using a multipart concept. We used several colors of materials and trimmed out certain areas to replicate the lifelike look and feel of the product.

Metallic Wreath

When a client comes to us with this type of project—one that already has a design and files ready for our team—we can typically prototype it within a few weeks.

Using their own graphic design software, our client created a wreath shape built from three-dimensional cubes. After generating an art file and an STL file for this shape, the customer provided Lane with the STL file so we could create a mold. Together with the client, we chose Acrylonitrile Butadiene Styrene (ABS) plastic as the base material, which would then receive a chrome laminate and printing. Using the mold generated from the client’s STL file, we formed and CNC-cut the parts for this project. We then bonded two parts together to make it a double-sided component.

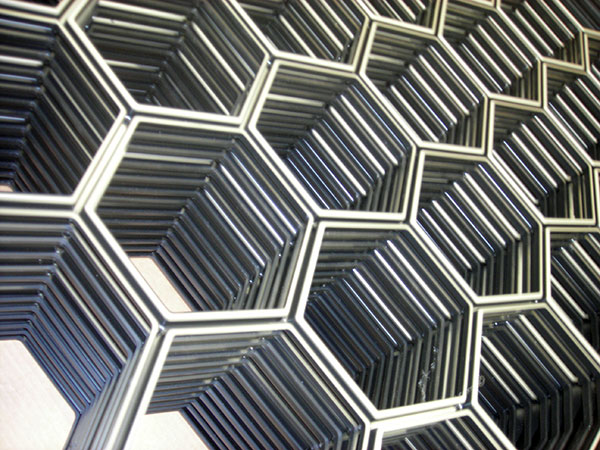

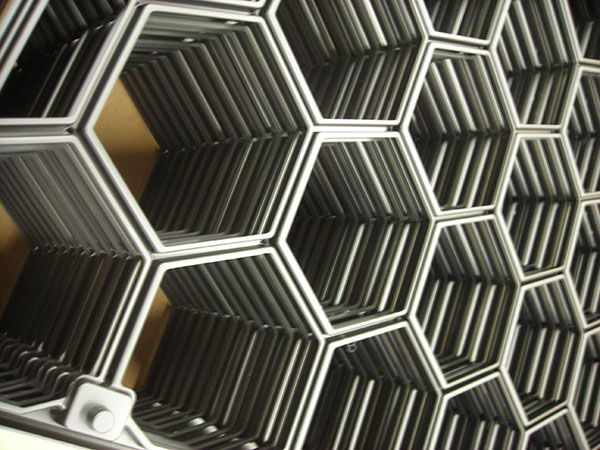

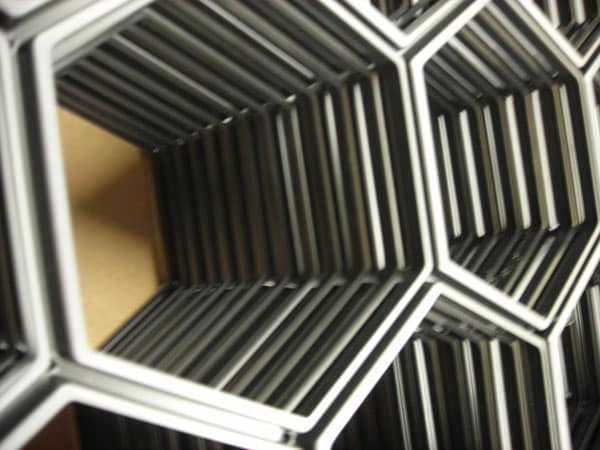

Hexagon Part

Our client came to Lane Co. looking for a large part that had minimal surface area, an effect that creates a lot of open space.

We applied our experience manufacturing geometrical shapes to create a part that used traditional honeycomb-like features in combination with rib-like features. The Lane Co. team leveraged our knowledge to work with the geometry of the part and address the client’s budgetary needs to trim the parts in the most economical fashion, providing additional value to the customer.

Acrylic Display Chairs

Lane Co. assisted in the production of full-sized acrylic chairs for display.

There was a great deal of CNC cutting necessary in the completion of this process, so the Lane team stepped in to help CNC the printed sheets of material (.5’’ acrylic) even though the client had CNC capabilities in-house. Our large thermoform heaters allowed us to bend the chairs into shape in a more economical way than many other fabrication shops, in a shorter amount of time and in two directions at once. This project was a great example of how Lane Co. can become an extension of a client’s own team, filling the capability gaps to get the job done with less expense and hassle.

Giant Candy Cane

This festive client was looking for a 27′ candy cane.

Lane Co. collaborated with the client to develop the geometry of the piece, using our CAD system to envision a custom thermoformed shell in multiple pieces. We then made a 1/4 scale CAD file, which was used to create the multiple molds and trim fixtures required of the design. After assembling the 1/4 scale version, the client approved moving forward with the full-size 27′ version. The Lane team then worked with our trusted partner vendors to create a skeleton to which the candy cane-colored thermoformed shells would be attached. Given the unique nature and scale of this project, Lane also assisted with the installation to ensure that everything went smoothly.

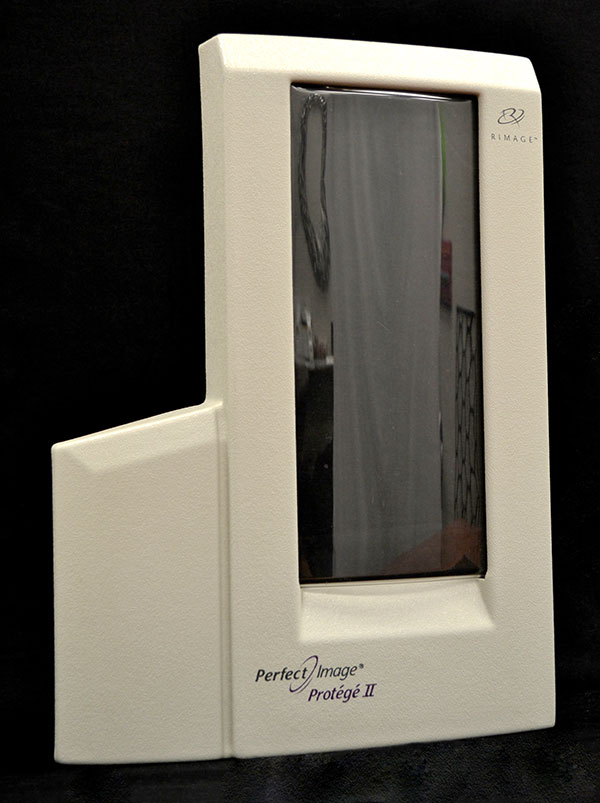

Machine Door with Window

For many years, Lane made a door with a small window for use in a commercial compact disc burner.

We decided to update the look of this component for a fresh feel. We leaned into the aesthetics of injection molding by using a female tool with a texture. The door and window were then formed and trimmed separately. Later, we bonded the parts together within tolerance to work effectively with the dehumidifier to which it would ultimately be attached.

Colored Letters

Lane Co. made fun, multi-color dimensional letters utilizing a “pop-through” technique in which openings are cut out of a flat sheet of material to create formed parts.

Custom colored materials can be used, as well as flood printing or printed patterns. This method allows for a clean transition between colors and patterns, providing a more finished look.

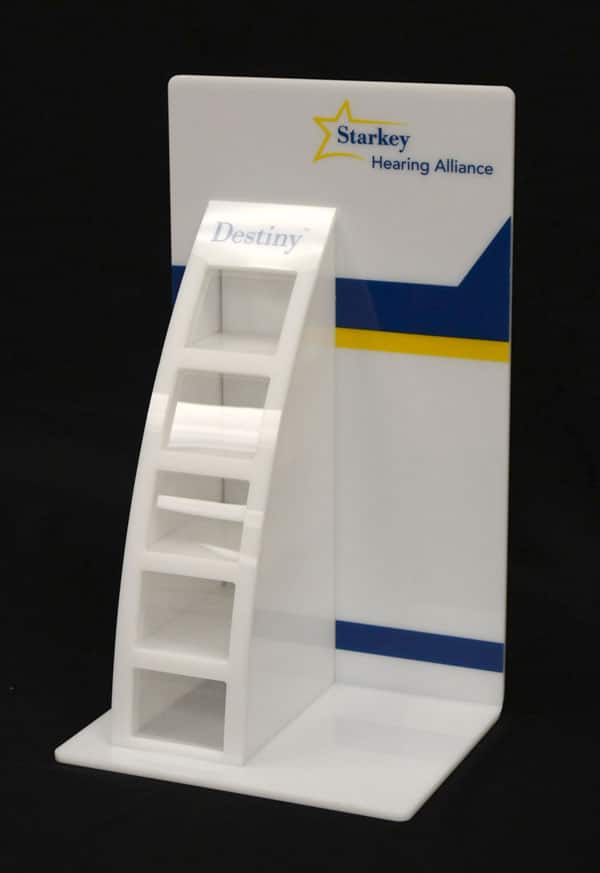

Acrylic Product Displays

Lane Co. was provided with an artist’s rendering and product dimensions to use in the creation of acrylic displays.

Using CAD software, we took the design and made it manufacturable for our process. This project is an excellent example of multi-part construction of displays, and of displays with additional or unusual elements, as the back of this design features a latching door.

Retail Kiosk

Using the customer’s design, Lane Co. made this large kiosk for a retail application with a screen and speakers housed within the part.

Due to the quick-turn nature of the retail display industry, Lane was required to move quickly and efficiently to fabricate the multi-piece mold in-house for rapid prototyping. The tool was also able to run production parts. Our team is highly experienced in rapid prototyping for retail and other industries, and we pride ourselves on both the quality and speed of our process.

Let’s work together.

Contact us today to request a quote for your project, or to learn more about our shroud manufacturing process.